1.pet resinsumo

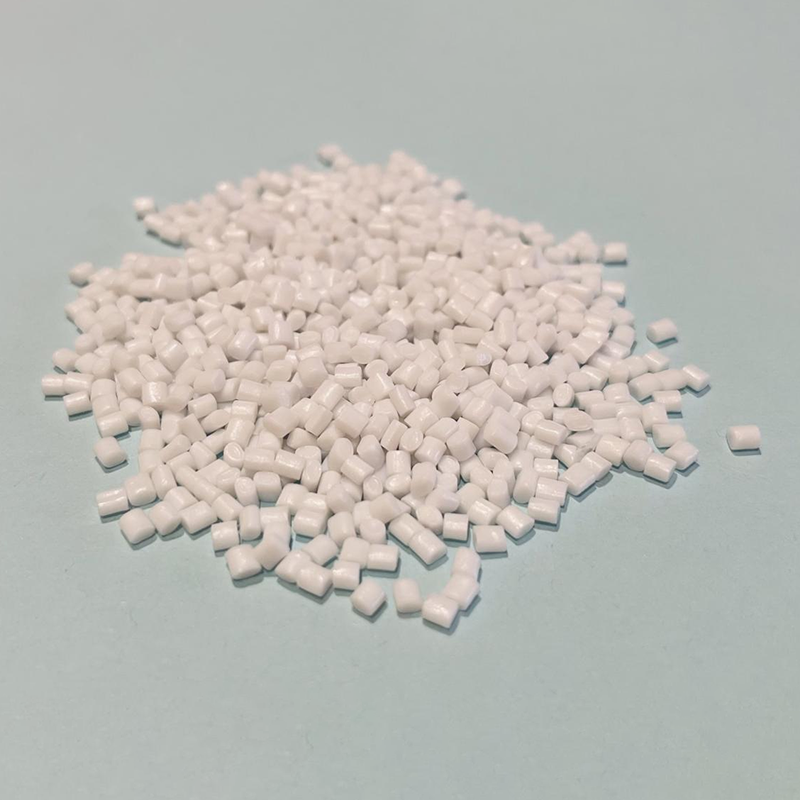

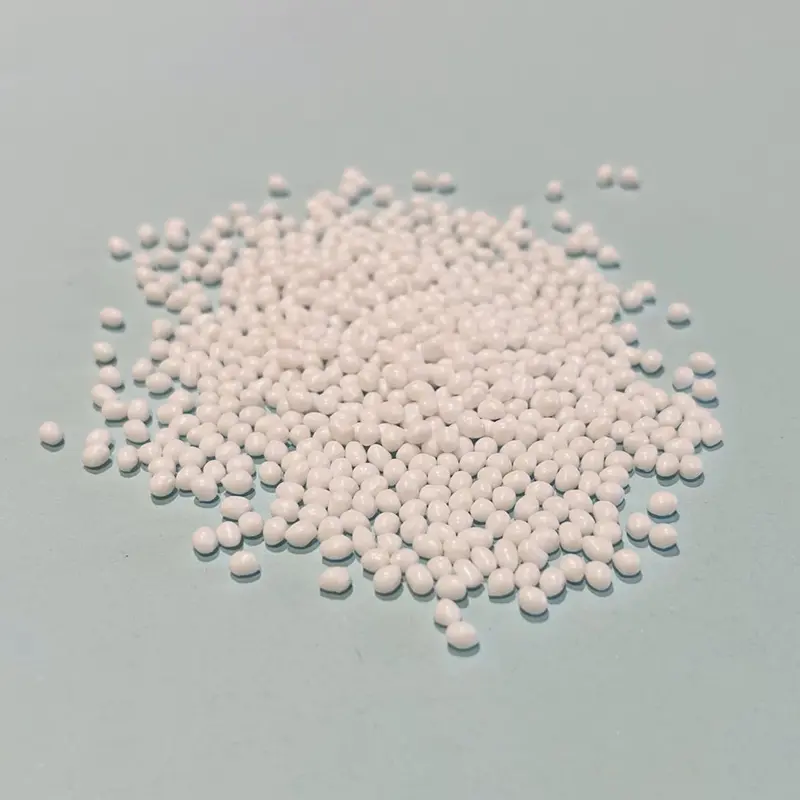

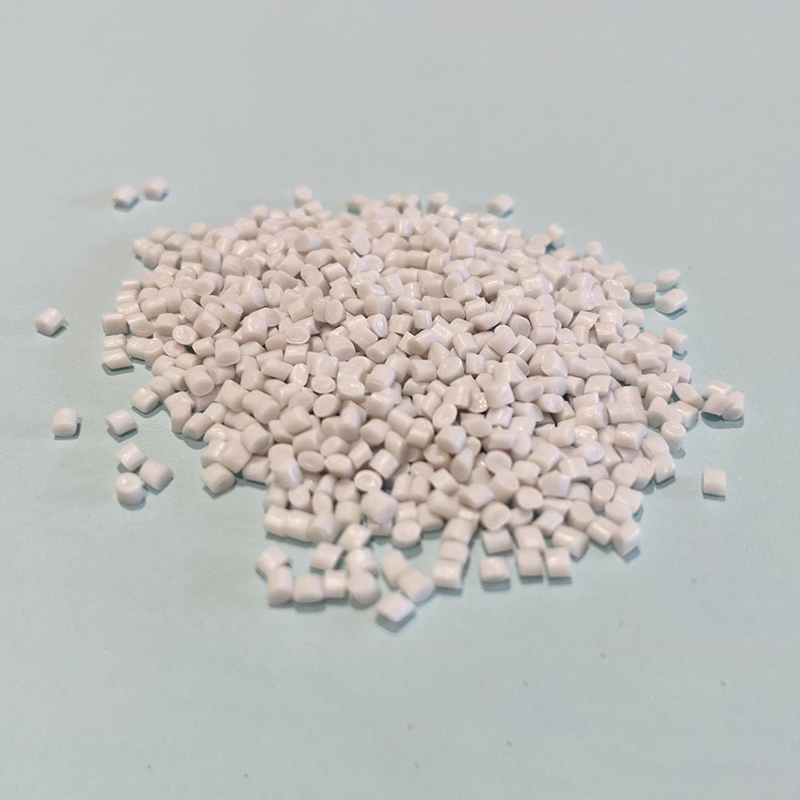

PET kemikari zita Polyethylene terephthalate, inozivikanwawo sepolyester, kemikari formula COC6H4COOCH2CH2O.Dihydroxyethyl terephthalate yakagadzirwa ne transesterification ye dimethyl terephthalate ne ethylene glycol kana esterification ye terephthalate ne ethylene glycol, uye ipapo polycondensation reaction.Iyo icrystalline saturated polyester, chena yemukaka kana yero yakapfava, yakanyanya crystalline polymer ine yakatsetseka uye inopenya.Iyo yakajairika resin muhupenyu uye inogona kukamurwa kuita APET, RPET uye PETG.

PET ichena yemukaka kana yero yakareruka, inonyatso crystalline polima ine nzvimbo yakatsetseka, inopenya.Iine zvakanakisa zvemuviri uye zvemagetsi zvimiro munzvimbo yakakura yekupisa, tembiricha yekushandisa kwenguva refu inosvika 120 ℃, yakanakisa magetsi ekudzivirira, kunyangwe pakupisa kwakanyanya uye frequency yakakwirira, midziyo yayo yemagetsi ichiri yakanaka, asi kushomeka kwecorona, kuramba, kuneta kuramba, friction resistance, dimensional kugadzikana zvakanaka kwazvo.PET ine ester bond, kuora kuchaitika pasi pekuita kweasidhi yakasimba, alkali yakasimba uye mupfu wemvura, kuramba kune organic solvents, kunaka kwemamiriro ekunze.

2.resin properties

PET ine yakanaka creep resistance, kuneta kuramba, friction resistance uye kugadzikana kwedimensional, kupfeka kudiki uye kuomarara kwakanyanya, uye ine kuomarara kwakakura mu thermoplastics: kuita kwakanaka kwemagetsi ekudzivirira, kukanganiswa netembiricha, asi kushomeka kwekona.Isiri-chepfu, kuramba kwemamiriro ekunze, kugadzikana kwakanaka kunopesana nemakemikari, kunyura kwemvura yakaderera, kuramba kune isina simba acid uye organic zvinonyungudutsa, asi kwete kunyudzwa kwemvura kusingadzivirirwe, kwete alkali resistance.

PET resinine yakakwirira girazi tembiricha tembiricha, inononoka crystallization mwero, kureba kuumbwa kutenderera, kureba kuumbwa kutenderera, hombe kuumbwa kuderera, kuderera kwechimiro kugadzikana, brittle crystallization molding, kushoma kupisa kuramba.

Kuburikidza nekuvandudzwa kweiyo nucleating agents uye crystallizing agents uye girazi fiber reinforcement, PET ine zvinotevera maitiro mukuwedzera kune zvivakwa zvePBT.

1. Thermal deformation tembiricha uye tembiricha yekushandisa kwenguva refu ndiyo yakanyanya mu thermoplastic general engineering mapurasitiki.

2. Nekuda kwekupisa kwakanyanya, iyo PET inokwidziridzwa inoiswa 10S mune solder bath pa250 ° C, inenge isina deformation kana discoloration, iyo inonyanya kukodzera kugadzirwa kwemagetsi nemagetsi zvikamu zve solder welding.

3. Simba rekukotama ndiro 200MPa, elastic modulus i4000MPa, creep resistance uye kuneta zvakare zvakanaka kwazvo, kuoma kwepamusoro kwakakwira, uye mechanical properties yakafanana ne thermosetting plastics.

4. Sezvo mutengo we ethylene glycol inoshandiswa mukugadzirwa kwePET inenge hafu yebutanediol inoshandiswa mukugadzirwa kwePBT, PET resin uye yakasimbiswa PET ndiyo mutengo wakaderera pakati peinjiniya mapurasitiki uye ane mari yakawanda yekuita.

Kuvandudza PET zvivakwa, PET inogona kusanganiswa nePC, elastomer, PBT, PS kirasi, ABS, PA.

PET (yakagadziridzwa PET) inonyanya kugadziriswa nekuumbwa kwejekiseni, uye dzimwe nzira dzinosanganisira extrusion, blow molding, coating uye welding, kuisa chisimbiso, machining, vacuum coating uye dzimwe nzira dzechipiri dzekugadzirisa.Nyatsoomesa usati waumba.

Polyethylene terephthalate inogadzirwa ne transesterification ye dimethyl terephthalate ne ethylene glycol kana esterification ye terephthalate ne ethylene glycol, uye ipapo polycondensation reaction.Iyo icrystalline saturated polyester, avhareji yemamorekuru huremu (2-3) × 104, chiyero chehuremu hwepakati kusvika kunhamba avhareji yemamorekuru huremu ndeye 1.5-1.8.

Girazi shanduko yekushisa 80 ℃, Martin kupisa kupikisa 80 ℃, tembiricha yekupisa deformation 98 ℃ (1.82MPa), decomposition tembiricha 353 ℃.Iyo ine yakanakisa michina zvinhu.High rigidity.Kuoma kwepamusoro, kunyura kwemvura kudiki, kugadzikana kwakanaka kwechimiro.Kusimba kwakanaka, kukanganisa kuramba, friction resistance, creep resistance.Yakanaka makemikari kuramba, soluble mu cresol, concentrated sulfuric acid, nitrobenzene, trichloroacetic acid, chlorophenol, insoluble mu methanol, ethanol, acetone, alkane.Kushanda tembiricha -100 ~ 120 ℃.Kubhenda simba 148-310MPa

Kutorwa kwemvura 0.06% -0.129%

Impact simba 66.1-128J /m

Rockwell kuoma M 90-95

Elongation 1.8% -2.7%

3. teknolojia yekugadzirisa

PET kugadzirisa inogona kuve jekiseni kuumba, extrusion, kuvhuvhuta, kupeta, kusungirira, machining, electroplating, vacuum goridhe plating, kudhinda.Zvinotevera zvinonyanya kusuma marudzi maviri.

1. Jekiseni nhanho ① tembiricha kugadzika: nozzle: 280 ~ 295 ℃, pamberi 270 ~ 275 ℃, pakati forging 265 ~ 275 ℃, pashure 250-270 ℃;Screw kumhanya 50 ~ 100rpm, mold tembiricha 30 ~ 85 ℃, amorphous mold iri 70 ℃, kumashure kumanikidza 5-15KG.② Muedzo dehumidification dryer, zvinhu chubhu tembiricha 240 ~ 280 ℃, jekiseni kumanikidzwa 500 ~ 1400 ℃, jekiseni kuumba tembiricha 260 ~ 280 ℃, kuomesa tembiricha 120 ~ 140 ℃, kutora 2 ~ 5 maawa.

2. Muchikamu chemufirimu, PET resin inochekwa uye yakafanoomeswa kudzivirira hydrolysis, uye ipapo amorphous thick sheet inobudiswa mu extruder pa 280 ° C kuburikidza neT-mold, uye dhiramu inotonhora kana inotonhorera inodzimwa kusvika. chengetedza iri muchimiro cheamorphous chekutarisa kusimba.Pepa gobvu rinobva ratambanudzwa netende kuti riite PET film.

Longitudinal kutambanudza ndiko preheat shizha gobvu kusvika 86 ~ 87 ℃, uye panguva iyi tembiricha, tambanudza kanenge ka3 uchitevedza nzira yekuwedzera kwendege yakakora, kuitira kuti kutarisisa kwayo kugone kuvandudza dhigirii rekristaro kusvika kune tembiricha yepamusoro: the transverse preheating tembiricha ye98 ~ 100 ℃, iyo tensile tembiricha ye100 ~ 120 ℃, iyo tensile reshiyo ye2.5 ~ 4.0, uye tembiricha yekupisa ye230 ~ 240 ℃.Iyo firimu mushure mekutenderera uye yakatambanudzwa yakatambanudzwa inodawo kuve-yakadzika-yakaita kuti ibvise iyo firimu deformation inokonzerwa nekutambanudza uye kuita firimu nekugadzikana kwakanaka kwekupisa.

Nguva yekutumira: Sep-05-2023